BigRep and Forward AM Introduce Concrete Formwork Material for the Construction Industry

Written by: MANUFACTUR3D

Publish Date: May 14, 2021

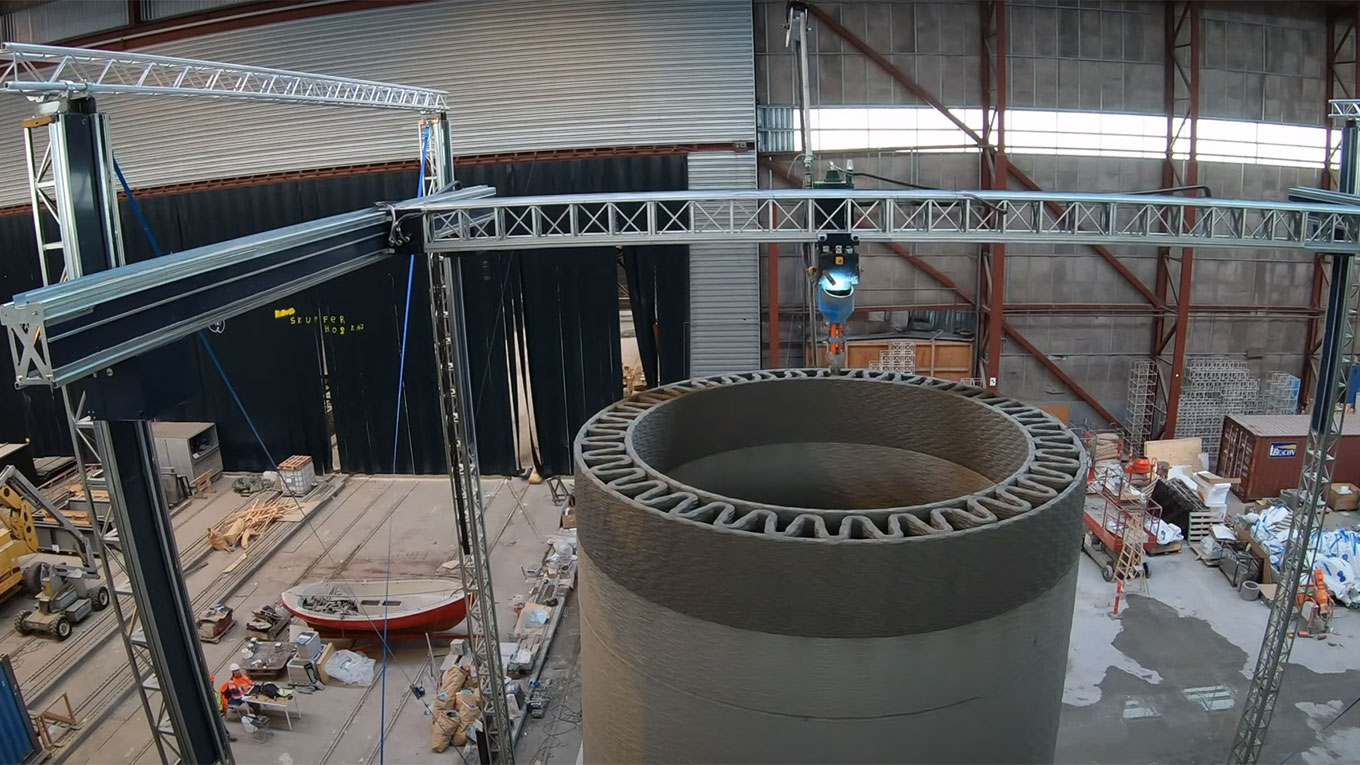

Architecture is the representation of a cultural era. By transforming its design language, creators can redefine the world around us. However, reality comes crashing down when conventional formwork solutions quickly reach their limits as construction elements become more complex. To overcome this challenge, Forward AM and BigRep are expanding their partnership and have joined forces again to leverage the synergies between their main areas of expertise: Virtual Engineering, Additive Manufacturing, advanced material development, and large-format printing.

Formwork, the moulds used in concrete construction, can make up 40 – 60% of a total budget, especially for complex shapes. Without 3D printing, some designs like organic geometries, double-curved surfaces, and cavities are simply not feasible to produce. They require highly skilled labourers to build customized formwork resulting in high costs, long lead times, and material waste.

“We are excited to work with Forward AM to bring more solutions to the architecture and construction industry. Our customers are seeing huge gains in terms of cost and speed thanks to our large-format machines and the new CONCRETE FORMWORK filament. Our solutions are opening the doors to many new possibilities.”– Dr. Sven Thate, Managing Director of BigRep

BigRep 3D printers, which are up to 1 cubic meter in build volume, can produce large, complex formwork up to 3x faster at a fraction of the cost of traditional methods. With BigRep’s new CONCRETE FORMWORK filament enabled by Forward AM, the massive benefits of 3D printed formwork are yours for the taking.

“At Forward AM, we developed a highly dimensionally stable, rigid formwork material, especially tailored to work seamlessly on the BigRep’s large-format3D printers. We are excited to be able to deliver this ready-to-use, end-to-end fabrication solution for bespoke formwork.”– François Minec, Managing Director BASF 3D Printing Solutions

Demonstrating the material’s effectiveness and advantages for the construction industry, Forward AM and BigRep showcase the “Bespoke Stair at Nest Step2,” designed by DBT at ETH Zürich with ROK, SW Umwelttechnik, and WaltGalmarini. The innovative concrete staircase expands the design possibilities of structural architectural elements, while minimizing costs, material waste, and skilled labor. NEST, to be built at EMPA in Zürich, is an innovative building utilizing digital fabrication and circular economy.

About the Author

This article is written by MANUFACTUR3D

Read the original post here.